-

Posts

1,896 -

Joined

-

Days Won

13

Content Type

Profiles

Forums

Events

Posts posted by Etern4l

-

-

4 minutes ago, Raiderman said:

So I have been looking at some custom loop kits, and found a Raijintek kit that I like. I have read a couple reviews, and most are pretty positive. What do you all think?

https://www.raijintek.com/en/products_detail.php?ProductID=153

How much is that kit roughly?

-

A roaring success @Mr. Fox. Approx. 20C temp reduction on first installation with PTM7950 on the die, and TF7 on the heatsink (prob my worst paste, just to put something on for the initial calibration). I haven't even validated the heatsink alignment. Of course, this vs rather poor initial state, but still.

Many thanks for advising this somewhat radical approach! Granted a few things could have gone wrong, but didn't:

* Rockit Cool sent me the kit straight away

* Most importantly, the delid worked (almost) perfectly - I say almost, because witih careful examination there is an ever so slight bend on the left wing (the one making contact with the pusher). By my eye it's less than 0.1mm, probably much less, it's barely visible, so I'm considering it immaterial, and would be very easy to lap off if needed

* Cleanup was the most consuming part, both the silicone sealant removal and desoldering

BTW don't know why Rockit call solder "sodder" in their instructions - doesn't have a nice ring to it in British English :D, but I guess that's appropriate given how annoying the "sodder" is to remove lol

* PTM7950 was about as annoying to apply as usual, meaning I'd much rather use the paste, but the relidding tool worked perfectly. The copper IHS landed well clear of all the caps at the bottom and left side of the IHS, and fits the Thermaltake frame well. Screwing the contact frame on was a little bit more difficult, I had some trouble engaging the bottom two screws, but it worked in the end.

One thing that bothers me is I didn't have Loclite "Gel Control", and just wanted something very temporary so went with the much cheaper "Power Gel".

It's a pretty weak glue in my experience, so my assumption was that there is no risk of this damaging the PCB, and the downside vs using "Gel Control" is that it might just break off very easily. Please advise if there are some known more serious concerns around this.

Given that I'm more than happy with where things are at the moment (my intention is not to exceed 250W of constant power draw on this chip), I will take a moment to check the heatsink alignment and apply what's probably the best traditional paste in my arsenal (Alphacool Apex), and defer further experiments until 7958 paste arrives, as this super-workable as is. At that point I will reopen and try two things:

* Conductonaut on the original IHS which looks great after cleanup

* 7958 on both sides of the copper IHS

And maybe Conductonaut on the copper IHS depending on prior results and keeping in mind my modest power draw requirements.

Again, many thanks to you and others for the various pieces of pro knowledge and support. In case it wasn't apparent, I was getting a bit frustrated with the thermal issues, and the advice to delid was absolutely spot-on (although the new faster pump/larger backplate AIO is probably also helpful, I will test vs Arctic if I have the time). Time to pop the champagne, cheers!

-

5

5

-

1

1

-

1

1

-

-

45 minutes ago, JeanLegi said:

It is for sure not for CPU and GPU dies.. only VRM's.

VRAM can certainly die as well.

-

1

1

-

-

1 hour ago, Mr. Fox said:

Stock MSI vBIOS. Will move to the Galax HOF soon. Cold air is keeping core max to 40°C and core max to 48°C with max fans and boosting to 3150 (+225) and +1650 memory offset.

https://www.3dmark.com/3dm11/15686404

This excites me almost as much as if it were my own experience. Super happy for you. The delid is long overdue. I anticipate your thermal issues will be largely a thing of the past now.

Heating up the IHS is probably what allowed you to push off the IHS without damaging/denting the side of it with the push block of the delid tool. I don't heat the IHS. I will try that the next time. How did you warm it up? I have not delidded the 13900KF in my work computer because I don't ever push the CPU overclock hard enough to thermal throttle on that machine. 5.7GHz on P-cores is as high as I have ever pushed it and that is my daily driver clock on the work machine. Maybe I will try heating it up when I delid that CPU and see if it avoids denting the side of the IHS.

Well, it's fair to say you are the spiritual father of this project! Glad this seems to have worked so far, so we can share an excitement rather than aggravation lol

I used a heat gun set to 150C and fired at close range through the window for about a minute, then tightened the screw until resistance intensified uncomfortably (I guess the solder was cooling down and setting), then repeated. I removed the top cover a few times to assess the situation, and in the hope I can get the IHS off already. No joy, had to keep going until the pusher was all the way in, basically the solder got smeared off the die. I will post some pics when the dust settles.

BTW special "thanks" to Intel for placing 3 caps < 0.5mm off the bottom edge of the IHS. One tiny wrong move and those might have gotten decapitated. Took me like half an hour to get the silicone off that area. Will require extra care during relidding.

-

3

3

-

1

1

-

2

2

-

-

Yay, the delid op seems to have worked. Pretty smooth actually, the CPU really needed this - there wasn't even a pop to speak of, although I did heat the IHS up. No visible damage to the PCB or the IHS. Now onto the cleanup. Nurse!

Edit: looking at how well the removal of the silicone residue is going, nurse @Etern4lshould be done by tomorrow evening if he hurries up lol

-

3

3

-

2

2

-

1

1

-

-

1 minute ago, cylix said:

Tried the open beta of diablo IV, at the first glance I like it. Graphics and art direction are great, like blizzard used us to. Skill tree looks alright. Would love a better zoom level, I didn't see a slider to zoom out a little, right now is to cramped for me. But I don't know if I'll buy it. Don't have the time for so time eating games anymore. Last diablo that I finished was lord of destruction a long time ago. Diablo 3 I started it but didn't go far and abandoned it because of the time. 😅

Yeah, probably more of the same. For Diablo to move to the next level, they would either need to make it more realistic and push the rating from M to A, which they won't, or come up with a really cool out of the box story, which they are unlikely to do either.

-

1

1

-

-

1 hour ago, Papusan said:

Never assume all boards have exactly same readout of voltage. And as I said the +1.52v you see from some CPU-Z screenshots isn’t the voltage they run at 🙂

Same also for Jokebooks. Mostly VID is showed and not real core voltage. What you see is what you think it is 🙂

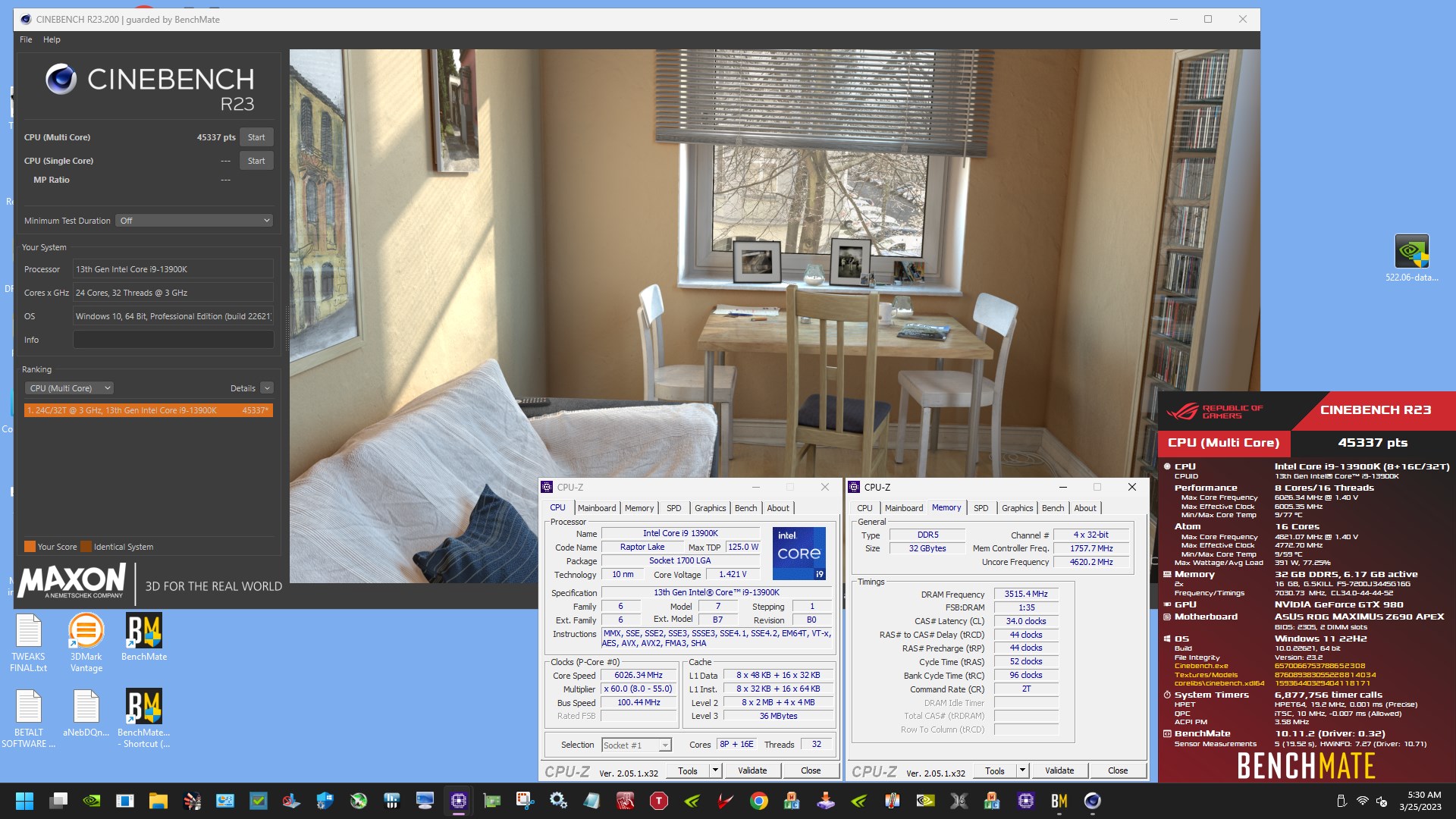

Yeah, yeah. You know what they say: trust, but verify. Since we can't verify (no video of the achievement yet I guess?), you are on the unfair overclocking watchlist bro ;)

BTW Not sure if this is connected to the recent sickening turmoil at Intel, sad news either way:

Gordon Moore, Intel co-founder and creator of Moore's Law, dies aged 94

-

2

2

-

-

16 minutes ago, Papusan said:

Asus board has the diesense reading so the voltage you see is socket sense which is much higher. Load voltage is closer to 1.359v.

And if you see voltage reading at +1.52v on a few screenshots it doesn’t necessarily mean you run voltage at that level 🙂

Then you have priority. Above normal priority in task manager the reading of temps and other values will be different/squwed.

Got it, just a bucket of Norwegian snow somehow pushed into the loop then ;)

10 minutes ago, MyPC8MyBrain said:personally i don't get the point in deleding then slapping IHS back on instead of direct die application.

in the past i used this Permatex 22072 Ultra Black Maximum Oil Resistance RTV Silicone Gasket Maker, small drop in each corner same as Mr. Fox advice. https://www.amazon.com/gp/product/B000HBIBOY

Yeah, I saw that one being advised, but given that I'm not making a gasket here (quite the opposite?), I went with the red Weld Silicone RTV sealant variant (but now will probably just use the Super Glue Gel as recommended by Rockit and @Mr. Fox). Also the "4 drops in the corners" advice is different to what @Mr. Fox is suggesting, which is just 2 little drops under the wings which makes sense to me. I'm wouldn't be relidding for resale, so would just want a minimal, easy to remove bond.

-

2

2

-

1

1

-

-

15 minutes ago, Mr. Fox said:

Bench-friendly ambient temperatures. Remember, @Papusanis The Snowman.

Currently in that part of the world... fresh, moist air

Haha, had the same thought but looked at Trondheim, it was -4C last night. I'm not sure that would have done it. Bro @Papusan is pulling a fast LN2 one on us here :) I mean these scores, voltages and temps without delidding have only one major explanation, unless I'm missing something.

-

1

1

-

1

1

-

-

6 hours ago, Papusan said:

I have just an average and non delidded 13900K. Not the nice delidded KS as bro @tps3443 tested. But the results is still quite ok. I would probably get +6.1GHz and above 46.000 in CBR-23 if I had it delidded and run direct die. It's what it is🙂 Sp111 on the P-cores so nothing special. Those will go into the Raptor refresh.

Nice bro. Max core temp 77C at 1.4V... Hmm, how, other than LN?

-

1

1

-

1

1

-

-

17 minutes ago, Mr. Fox said:

I love Evolution on Linux. It is what I use. By far the best Linux alternative IMHO.

Last time I checked there was no Windows version of it. Has that changed? It would suit many Windows users very well, for private personal use and basic small business email, task and calendar functionality.

Ah, the Windows version is indeed defunct. Guess Thunderbird is a solid option too.

-

2

2

-

1

1

-

-

25 minutes ago, ryan said:

Why on earth don't you guys use open office or other free alternatives. Plenty.

There is really just Libre Office. It's perfectly serviceable for most people. There is no Outlook, although obviously there are open source alternatives, such as Evolution. Evolution doesn't seem to have the ability to import/open .ost files, so migration wouldn't be the easiest (hence all the legal battles with M$ to force them to support open file formats and thus encourage some competition). Freedom isn't always provided on a silver platter, unfortunately - quite the opposite actually if we look at history.

-

5

5

-

1

1

-

-

The article suggested it is more of a chance to see an asteroid up close through some basic instruments, but I'm not sure how much of an opportunity it really will be. It's pretty small, and will just zip past Earth in a matter of minutes tops.

https://en.wikipedia.org/wiki/2023_DZ2

KK, magnitude 10-12 through binoculars, well done BBC.

-

1

1

-

-

18 minutes ago, Reciever said:

Its for this reason I probably am going to make the forums default to dark mode, Dark mode should be on as much as possible in my view.

For the longest time I've only used dark mode everywhere, but for the past year or so I have been exploring the light side. It's not bad, it's sort of energising. When I switch this to dark mode now, it doesn't feels right - kind of dull. Interesting I guess.

-

2

2

-

1

1

-

-

A 40-90m asteroid will be passing just 68,000km from Earth tomorrow. That's pretty close!

https://www.bbc.co.uk/news/science-environment-65061818

-

2

2

-

-

12 minutes ago, Ishayin said:

Doesn't the lm_sensors tool you mentioned previously provide that? E.g. via one of the graphical front-ends like psensor or xsensors?

Regrettably not, unless something's wrong with hardinfo's interaction with lm_sensors. Only shows temps, not fan RPMs. Need to do a deep dive into the config and maybe check out the tools you recommended, don't really trying them before, thanks.

-

1

1

-

-

51 minutes ago, Ishayin said:

There's also Powertop in case that helps:

https://github.com/fenrus75/powertop

https://wiki.archlinux.org/title/powertopHere's also a dump of links from my Zim wiki regarding CPU management and undervolting etc. on the off chance there's anything of interest among that lot:

CPU Tools

https://github.com/X0rg/CPU-X

https://github.com/amanusk/s-tuiCPU Frequency

https://ostechnix.com/cpu-power-manager-control-and-manage-cpu-frequency-in-linux/

https://extensions.gnome.org/extension/945/cpu-power-manager/

https://github.com/deinstapel/cpupower

https://ostechnix.com/improve-laptop-battery-performance-linux/

https://github.com/rickysarraf/laptop-mode-tools

https://github.com/rickysarraf/laptop-mode-tools/wiki/FAQ

https://github.com/rickysarraf/laptop-mode-tools/wiki

https://ostechnix.com/how-to-optimize-laptop-battery-life-with-tlp-in-linux/

https://linrunner.de/tlp/

https://github.com/linrunner/TLP

https://wiki.archlinux.org/title/CPU_frequency_scaling

https://itsfoss.com/cpufreq-ubuntu/

https://manpages.ubuntu.com/manpages/trusty/man5/cpufreqd.conf.5.html

https://github.com/vagnum08/cpupower-gui

https://cinnamon-spices.linuxmint.com/applets/view/70

https://github.com/SwallowYourDreams/cpu-control

https://www.linux-magazine.com/Issues/2021/246/auto-cpufreq

https://superuser.com/questions/265322/limiting-cpu-speed-in-a-virtual-machine

https://github.com/lpereira/hardinfo

https://www.techpowerup.com/forums/threads/my-script-for-setting-pl1-pl2-power-limits-in-linux.294190/

https://github.com/horshack-dpreview/setPL

https://askubuntu.com/questions/587978/can-i-upper-limit-the-cpu-frequency

https://github.com/opsengine/cpulimit

https://www.tecmint.com/limit-cpu-usage-of-a-process-in-linux-with-cpulimit-tool/

https://super-unix.com/ubuntu/ubuntu-how-to-permanently-set-cpu-power-management-to-the-powersave-governor/

https://askubuntu.com/questions/523640/how-i-can-disable-cpu-frequency-scaling-and-set-the-system-to-performance

https://www.maketecheasier.com/fix-high-cpu-usage-linux/

https://phoenixnap.com/kb/linux-cpu-temp

https://gitlab.com/corectrl/corectrl

https://gitlab.com/corectrl/corectrl/-/wikis/home#features

https://askubuntu.com/questions/1226254/set-max-tdp-of-intel-h-series-cpu

https://askubuntu.com/questions/556894/tlp-dont-change-cpu-frequency

https://www.mankier.com/8/turbostat

https://community.intel.com/t5/Software-Tuning-Performance/Is-there-an-energy-profiling-tool-to-monitor-CPU-power/td-p/1167463CPU Undervolting

https://www.phoronix.com/news/Intel-GUI-Linux-Undervolt

https://appimage.github.io/linux-intel-undervolt-gui/

https://github.com/lukechadwick/linux-intel-undervolt-gui

https://wiki.archlinux.org/title/Undervolting_CPU

https://miloserdov.org/?p=1932

https://github.com/georgewhewell/undervolt

https://github.com/mihic/linux-intel-undervolt

https://github.com/tiziw/iuvolt

https://github.com/kitsunyan/intel-undervolt

https://github.com/RobertCsordas/linux-intel-undervolt-toolI also have other links saved for use with GPUs if anyone is interested in that.

Wow, thanks a lot - please do share that GPU stuff. I would suggest opening a quick thread on that.

-

3 hours ago, Mr. Fox said:

That will work.

I really hate to see you gluing down the IHS to test the PTM7950 because even if it works well for a bit, it won't work as well as liquid metal and won't likely be as durable. There is really no space to fill between the die and IHS and I think it is not a great idea. But, if you are committed to it, then I am eager to see how it works out in spite of my skepticism.

FYI - When the CPU is clamped in place, there is no air gap between the PCB and IHS, so there is no way for a stray droplet of liquid metal to escape or leak out from under the IHS. Liquid metal sticks to itself and tends to bead, which makes the danger even less. It can't really wiggle its way out unless you just go nuts and bathe the CPU with an excessive application. So, no need for fear or excessive caution putting it between the die and IHS. You want to avoid any material that is resistant to compression under the IHS. You want a pure layer of liquid metal with no air space between the die and IHS or it will impair temps. The caution needs to happen on the outside of the IHS.

Cool, many thanks for your extensive comments and advice bro.

All we need now is a bit of luck with the delid lol

I will do some extra YT time on this tomorrow, but by and large I'm comfortable.

I am not necessarily planning on gluing the IHS down for the PTM7950 test, but even if I do, presumably it's trivial to undo the bond. As for the thickness thing, fortunately it melts away and it's not really a pad per se to begin with. Ideally I would test the 7958 paste, however, that's only just shipped from China, so will prob take 2-3 weeks to get here. I'm worried I won't be able to contain my inner surgeon for that long ;)

As for which one would work better, intuitively it would be the Conductonaut, but it may not be so simple. Yes, it's 80W/(mK) vs 8.5, but that's not the whole story. Gallium has 30W/(mK) thermal conductivity and it alloys with copper which is 400W/(mK), so you end up with a somewhat thicker layer of relatively high thermal resistance gallium-copper alloy (what the conductivity of that alloy is, I don't know, but it's likely lower than that of pure copper), whereas with pastes (the 7950 in particular) you likely get a thinner layer, but of relatively even higher thermal resistance material between copper and the nickel. I think there are two factors at play (in addition to the base thermal conductivity):

1. The actual thickness of the two respective layers, this alone would probably require instruments costing millions to measure.

2. Molecular structure could play a significant role too (unless it's already baked into thermal conductivity) - you mentioned that LM forms beads, what if it clusters at the molecular level as well, leaving micro/nano gaps? PTM7950 is supposed to have a long/branched molecules which are supposed to be of benefit, intuitively I would expect those to be smaller/squishier particles compared to those of metal alloys.

All we need is an scanning electron microscope to find out for sure lol. Or we can just test empirically :)

The above could be some of the reasons why we don't generally see such astonishing improvements between LM and other pastes in practice. People have been raving about 7950 for a reason, and in my experience (2 applications so far) the material performs really well indeed.

Reliability/durability shouldn't be a concern either, given it's an industrial-grade material, it seemingly continues to improve its fit between the two surfaces as time progresses (I've observed this as well, it's quite satisfying actually). The excess kind of pours out like a bit of molten lava just outside of the contact area. The main concern is the lack of legit availability in the US and Europe. Is this stuff toxic or something?

-

3

3

-

2

2

-

-

44 minutes ago, Mr. Fox said:

1. No. Never had a reason to. It will likely be thicker than liquid metal and more resistant to heat transfer and also physically less thermally conductive as a matter of pure science. The key to it working correctly is getting all of the old rubber off and (if necessary) sanding the underside of the lip to make sure it is not touching the PCB when set on top of the die. It should spin on the die without touching the CPU PCB. Apply liquid metal to both surfaces during assembly or it won't work well.

2. Use liquid metal and bake it in the oven for an hour or so. You could use the Quicksilver as well if you have leftover. Either one will work. Never have seen the IHS get stuck to the die before. Not saying it couldn't happen, only that I am unaware of it based on personal experience. The reason to do it is to stop the copper from absorbing the liquid metal. You let it absorb it in the oven before installing it. Then the liquid metal will last a very long time because it is not being wicked away into the copper.

3. Leaving it loose is best, just be careful if you are using the stock ILM and not let it slide. The ONLY thing to be concerned about with leaving it loose is dislodging the SMDs outside of the IHS. Otherwise, no need for concern. Installing or removing the CPU in a chassis that is vertical makes it more dangerous to be left loose due to human error. On a horizontal installation you just have to pay attention and not allow it to move around until you have it secured. I have used one small dot under each "wing" (one left and one right) of superglue GEL (the gel only, not regular super glue). I have also used one small dot of RTV silicon under each wing. No need for 4 spots to be glued. The only reason to do that is to keep it from moving around when installing or removing the CPU from the socket. Otherwise, reattaching it is a waste of time and just creates inconvenience later. Do not apply it on the outside corners. I have seen Dufus Jufus do that. Silly. Just put some nail polish on the SMDs outside of the IHS and you're good to go. If you use super glue GEL, it takes very little. Let it dry for 20-30 minutes under compression with the relid tool. You can release it later by soaking the CPU in acetone for 15-20 minutes. It will disolve the super glue and not harm the CPU.

Not the "ultra" just the regular control gel. It does not run and it is easy to control the amount applied. And, it is not as strong.

Edit: @Etern4l- bake the liquid metal on BOTH SIDES of the IHS - forgot to clarify that. Same reason, as given, but don't do only the underside. After baking, use the scuff pad that normally comes with liquid metal and polish it with Flitz and it will look like chrome/nickel.

Thanks bro. I already have this glue

but ordered the Gel Control as well. I guess the benefit is that it doesn't expand and is easier to remove.

Unfortunately, the mobo position has to be vertical, so extra safety measures will be necessary, although will be initially fitting horizontally. The plan (assuming the patient survives the delidding surgery) is:

1. I have some PTM7950 left, will try that for science. Don't have enough to apply on the IHS as well, so will use some good regular TIM on the outside. If results are exceptional, will stop there, if not will proceed down the LM route

2. Do the IHS baking

3. Apply MG Chemicals Actylic conformal coating on any caps etc on the PCB

https://www.amazon.co.uk/dp/B07B8RY7M6?psc=1&ref=ppx_yo2ov_dt_b_product_details

4. Apply Conductonaut

5. Add a little line of K5 Pro around the edges of the die as a dam

6. Glue up the wings as advised

7. If I decide to go with LM on the IHS as well, then I guess I will just use K5 Pro around the IHS (the contact frame will come in handy there) as a dam too - no point trying to use conformal coating on the half of the PC that might be exposed to spillage

Wish me luck :)

-

3

3

-

1

1

-

-

A few delidding questions guys:

1. Has anyone directly compared LM/Conductonaut with PTM7950/7958 between the die and the IHS?

2. Rockit recommends "seasoning" the copper IHS with their Quicksilver gallium paste (I suppose LM would work as well, albeit more expensive), ideally for a week. This is supposed to prevent the die and the IHS getting welded together, as well as improve the thermal performance. Have you done this, and if so, how long for?

3. What's your recommended re-lidding glue/technique? I've come across quite a few:

a) No glue - sounds like a bad idea as it would be difficult to keep the IHS still on the die

b) 4 small dots of super glue on the PCB, some people say super glue has low flash point and can damage the PCB

c) 4 small dots of silicone RTV glue on the PCB

d) 4 small dots of silicone RTV glue applied externally on the corners of the IHS (wouldn't that interfere with the contact frame?)

Thanks for any thoughts and tips.

-

1

1

-

-

7 hours ago, cylix said:

More bad news for Intel on the server side.

Nvidia enters the building 😅

Very interesting, so Nvidia launched an attack on the CPU front...

144 cores. Respect, although no clocks data given. Would be interesting to see what the pricing and performance of workstation-grade ARM CPUs looks like. I always liked RISC architecture. It was miles ahead of Intel back in the day. I think it almost died for a while mostly because they didn't manage or care to break through to the mainstream (Apple is changing that now). The CPUs were mostly used in things like Silicon Graphics workstations. You can see those machines in office scenes in the original "Jurrasic Park", along with Jeff Goldblum and the other dinosaurs :)

As Intel fans we don't talk about enterprise CPU prices @Mr. Fox lol

-

4

4

-

1

1

-

-

18 hours ago, Mr. Fox said:

Not if I ever get smart enough to learn from my past mistakes. My problem is I am far too forgiving and I should be more of a fanboy than an enthusiast. Then I wouldn't end up in that predicament. Skunks don't change their stripes. I should care about brand more than I do, because every time I prove that I don't care I end up dissatified with the outcome.

Every time I am dumb enough to give them another chance they show me why I stopped giving them chances and scratched them off my list of acceptable options the last time. X570/5950X was a hard fail and the worst platform I can remember ever having owned before in spite of all of the bragging and sword rattling by fanboys. It was an absolute joke and I allowed it to happen because I don't care about brand.

AMD is a poser in the enthusiast space and they prove that to me every time I allow my curiosity as an enthusiast to cloud my judgment. I say that based on what they do, and how it affects me. When they gain ground on performance, they draw back a bloody stump on another metric. One step forward, then one or two steps backward, because the underlying architecture is an engineering abortion that sucks.

Companies do change. Remember it was AMD who gave us the 64 bit x86 architecture, while things at Intel went sideways for a while with Itanium.

What is the underlying architectural problem with Zen 3 and 4? I mean something is not quite optimal if they are merely trading blows with Intel despite the massive process advantage.

If you are just looking at it from the perspective of overclockability/tweakability, then still Intel every time I guess.

BTW guys, what's the story with ring voltage and ratio? What's the default ring ratio for the 13900K (for some reason MSI board doesn't show this, or I missed it), do you guys touch the voltage or leave it on auto, assuming fixed CPU ratio mode+voltages scenario.

-

5

5

-

-

The

4 hours ago, Tenoroon said:I saw this the other day and laughed my head off, hopefully this won't need to be a real job!

This would be pointless, just like all those sham revolving door AI ethics committees. The time to pull the plug on the whole thing, starting with the companies responsible, is now. Will humanity do it? Of course not, due to globally insufficient natural intelligence.

-

2

2

-

1

1

-

-

16 minutes ago, Papusan said:

That train has gone.

Well, let's hope Intel is not gone. Certainly the stock market doesn't think much of their prospects (as opposed to AMDs).

Seems to me their loyal customer base, often going back decades, is their greatest asset in the current testing conditons. I wonder if "progressive business ideas" such as disabled features, activation fees, and seriously compromised quality to shave a few bucks off a $700 CPU etc. constitute the best strategy for them to retain those customers.

-

1

1

-

*Official Benchmark Thread* - Post it here or it didn't happen :D

in Desktop Hardware

Posted

IC Diamond is obviously not made of pure diamond... The content must be basically trace at best, or the TIM would be unaffordable. Still, it was supposed to be pretty good and durable, however, it can scratch the surfaces it's spread on, and seems hard to find. Better options are available these days I guess.